精益生产

KPI

生产效率类指标

品质管理类指标

生产成本管理类指标

年度生产计划

设备管理怎么做

设备管理的OEE﹑MTBF﹑MTTR﹑MTTF计算方法

WCM术语手册

TPM到OEE再到OPL 术语缩写

药品生产领域ISA95结构

ISA88全套批次控制标准

ISA95标准介绍

MES是如何遵从ISA-95标准

制造运营管理与ISA95模型

指标驱动、数据优先、工业数字化转型的经验分享

生产绩效管理与MOM的“那些事”

一文读懂制造运营管理(MOM)

ISA-95 终极指南

MES与哪些企业管理的核心KPI相关

制造业如何开展高效的数据分析

智能制造

doc88标准下载

ISA95.PART3翻译整理 制造运营管理的活动模型

MES系统的发展历程和标准体系

智能社会与卓越运营解决方案

aws mapping-to-the-isa-95-model

Everything You Need to Know About ISA-95

ISA-95-01

ISA-95-02

ISA-95-03

ISA-95-04

ISA-95-05

六西格玛绿带和黑带

六西伽马和TQC

成本会计日常工作

execel模版

PMC生产物料控制

生产企业成本会计岗位

制造费用

cip 清洗成本核算方法和流程

灌装线方案

作业成本法的产生、发展与应用

管理会计

食品工厂设计工艺计算之物料衡算

食品工厂物料衡算

PDCA闭环思维

本文档使用 MrDoc 发布

-

+

首页

Everything You Need to Know About ISA-95

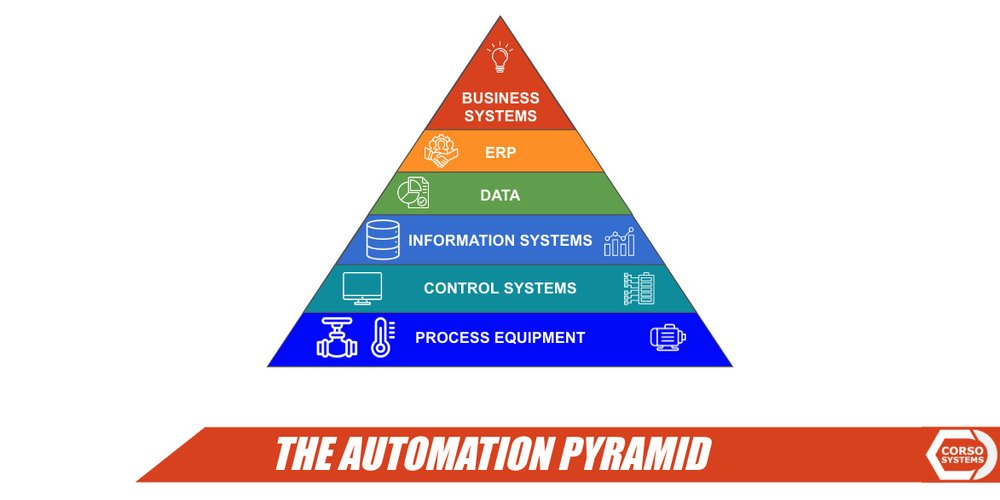

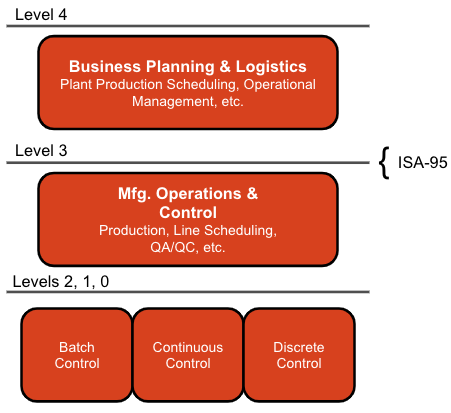

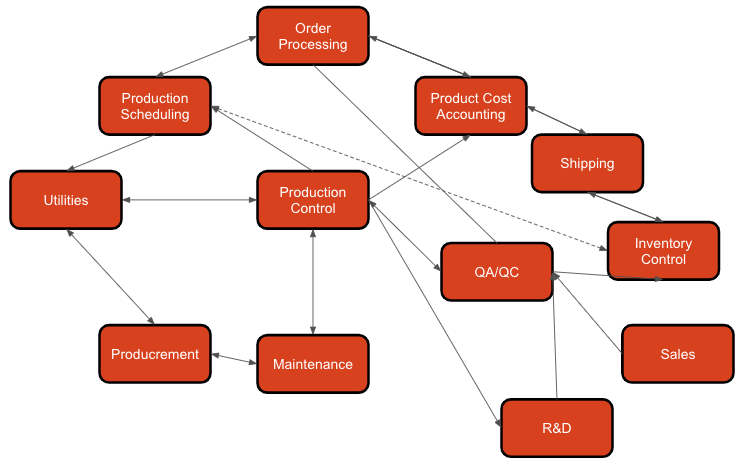

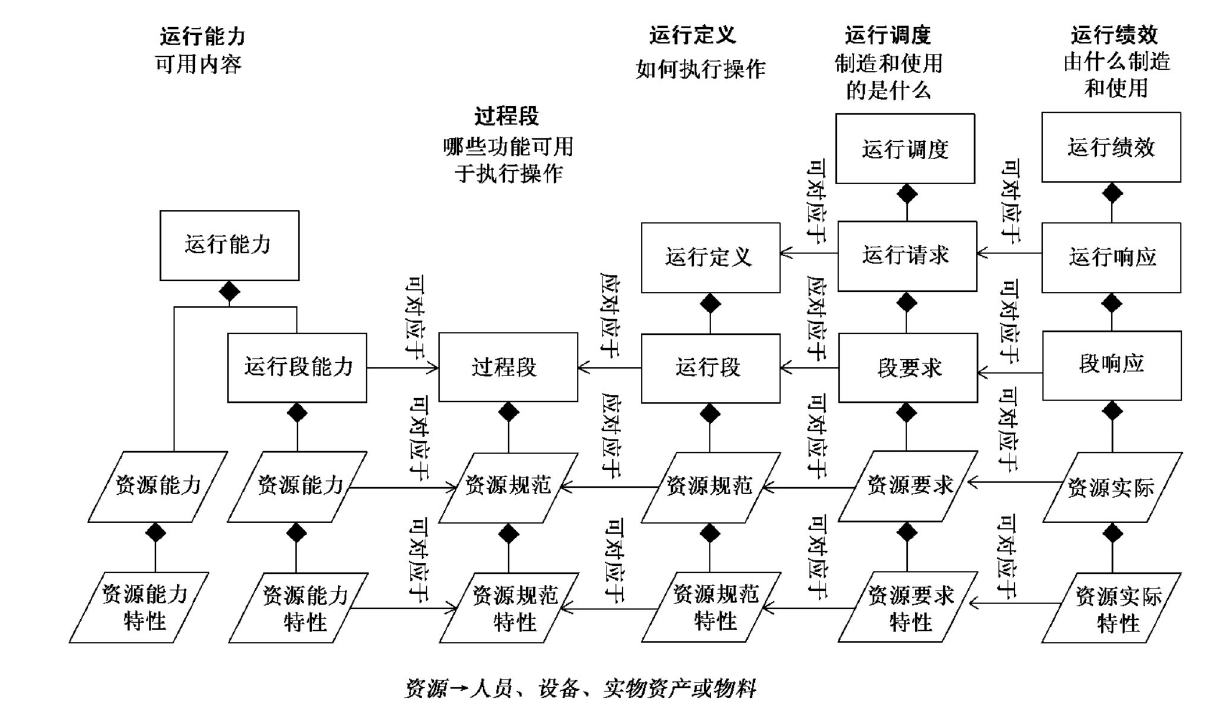

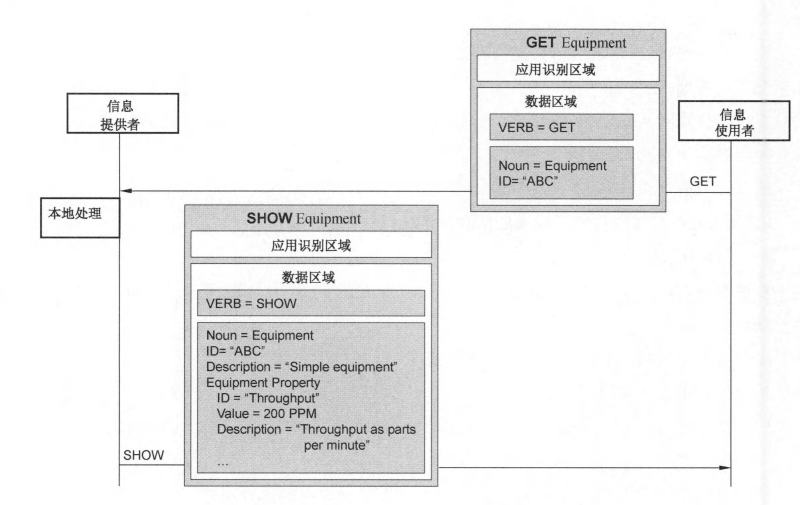

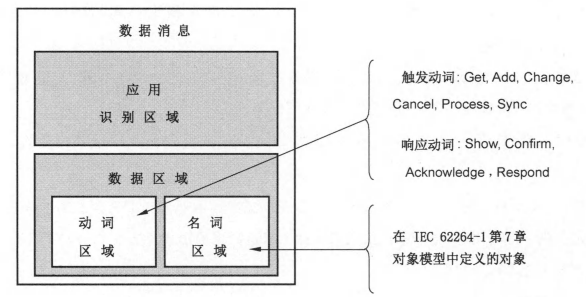

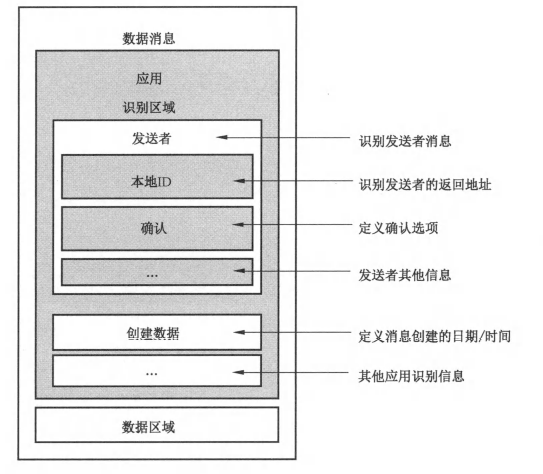

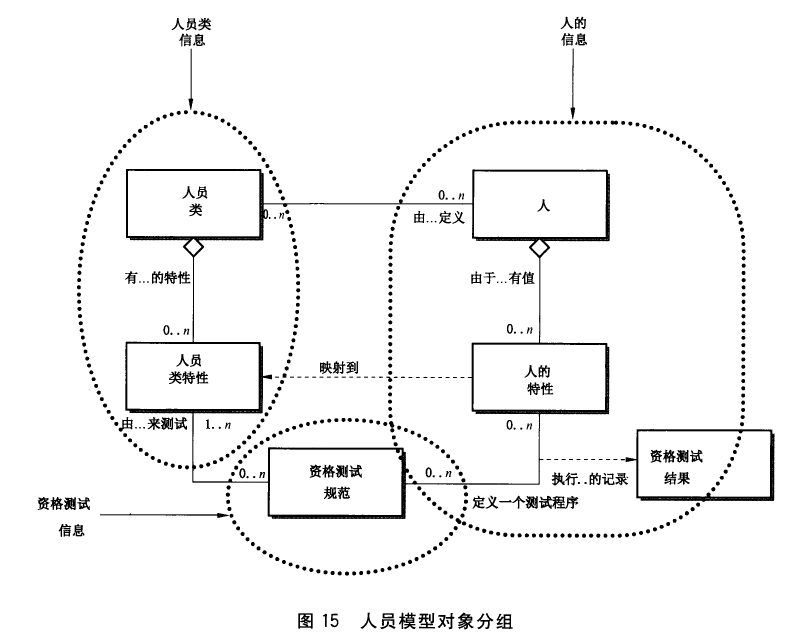

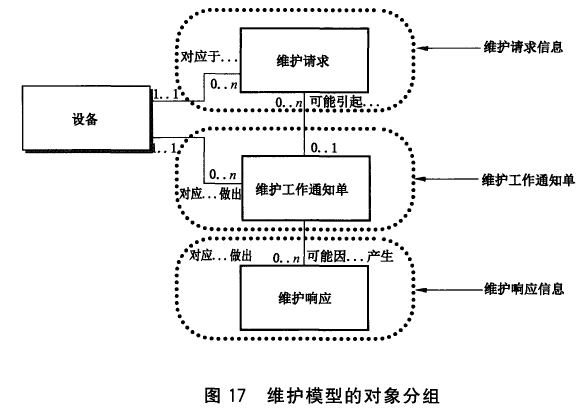

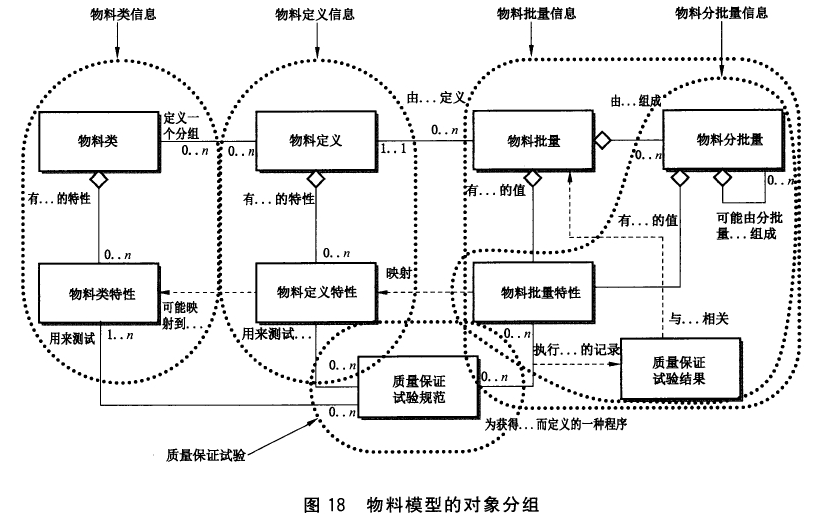

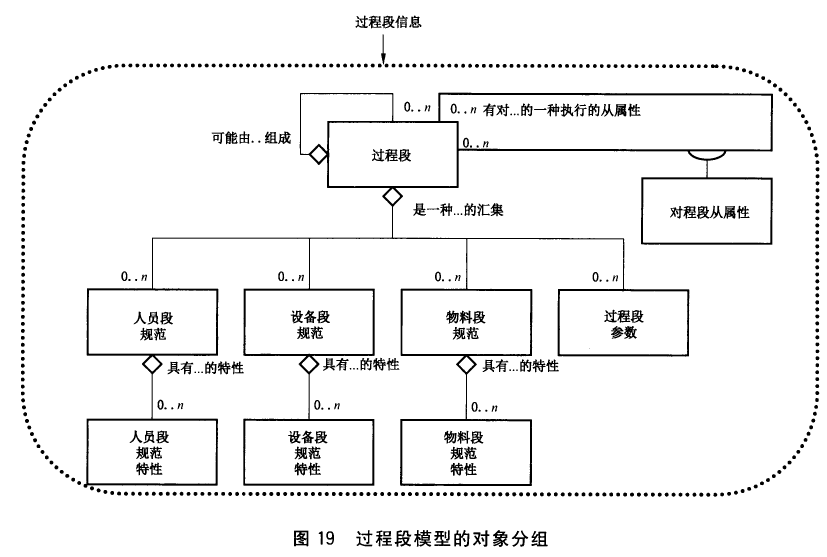

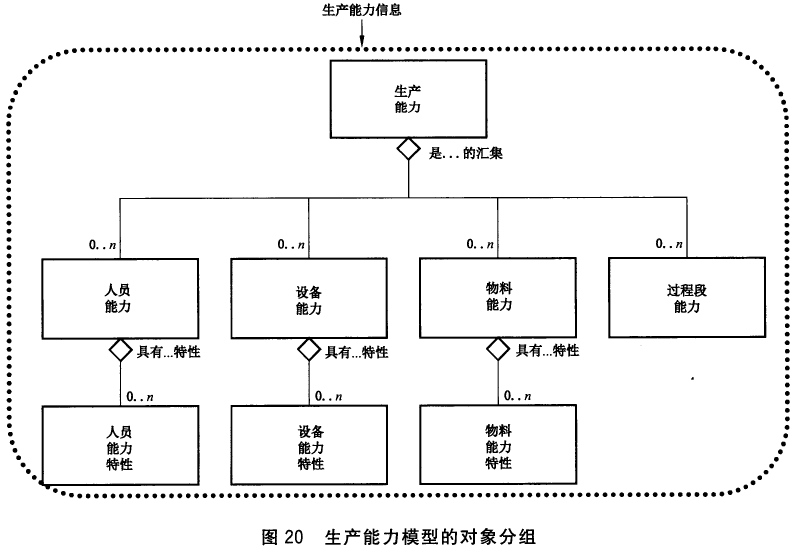

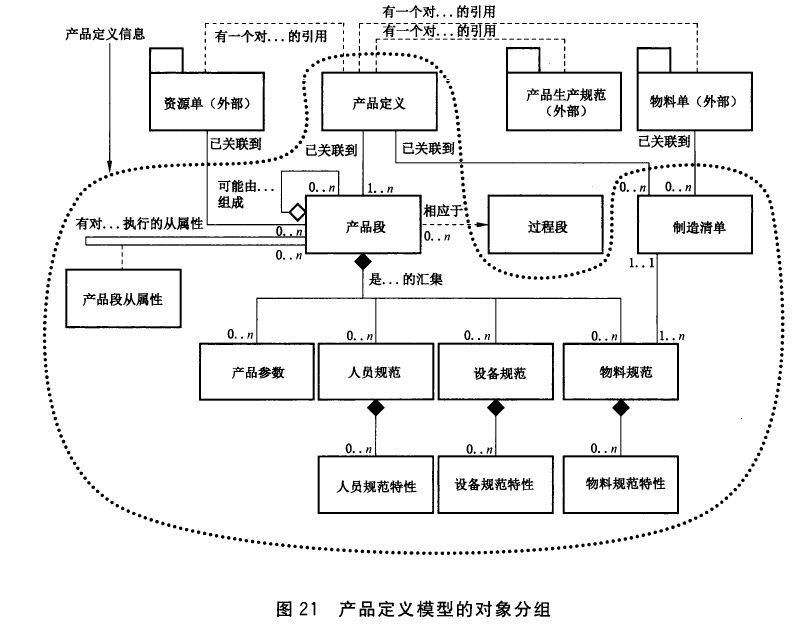

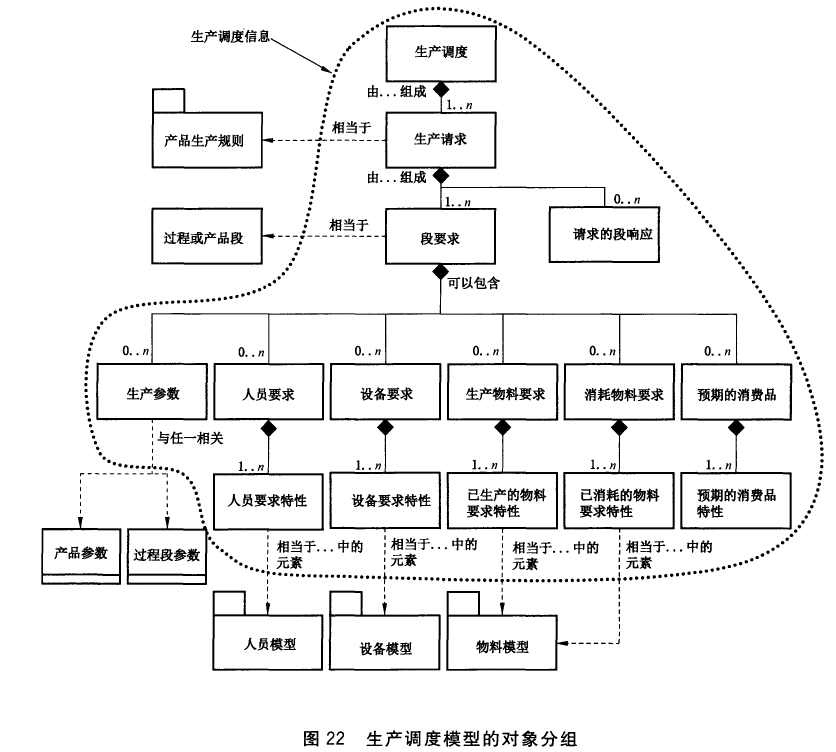

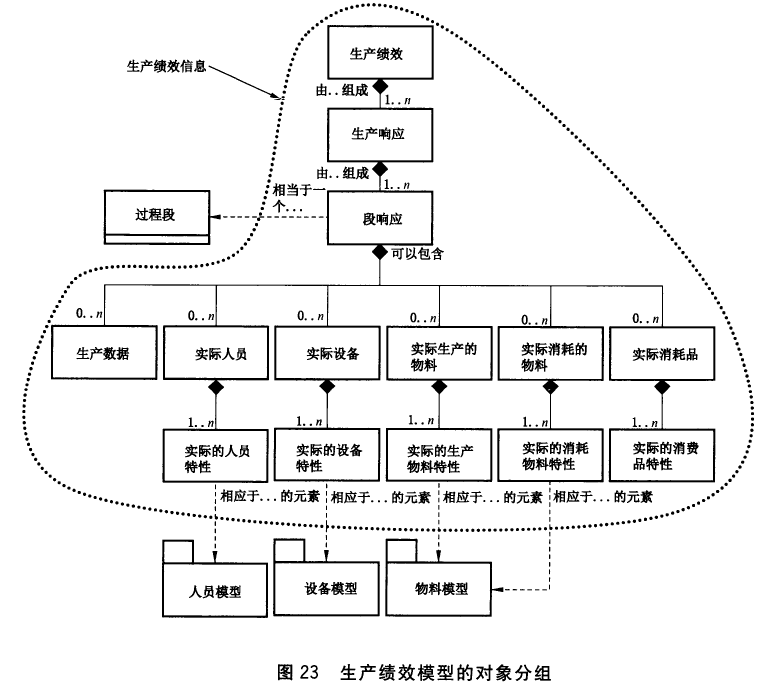

近年来,ISA-95在自动化领域已成为一个无处不在的术语。似乎任何声称能够进行企业级集成的系统都必须包含某种形式的ISA-95合规性。虽然我们听到了很多关于ISA-95的讨论,但很少有资源探讨它如何适用于当今世界。有些人甚至开玩笑说,“ISA-95”中的“95”意味着它在1995年是相关的,但在2023年不再相关。这在某种程度上是一个公平的评估,考虑到自1995年以来技术发展的巨大进步——许多问题现在通过诸如MQTT和统一命名空间等技术更容易解决。但是,模拟业务并定义信息流以加速集成时间和价值的整体概念是永恒的。 In recent years, ISA-95 has become a ubiquitous term in automation. It seems like any system that claims to be capable of enterprise level integrations must include some form of ISA-95 compliance. While we’ve seen a lot of talk about ISA-95, very few resources discuss how it is applicable to the world today. Some even joke that the "95" in "ISA-95" means it was relevant in 1995, but not in 2023. It’s a somewhat fair assessment, given how far technology has come since 1995—many problems are much easier to solve with technology like MQTT and Unified Namespaces. But, the overall concept of modeling a business along with defining the flow of information to speed up integration time and value are timeless concepts. In this post, we’ll discuss the what and the why of ISA-95 along with where it does and doesn't apply to modern control systems. We’ll outline what you actually need to know to use ISA-95 when designing Enterprise system architectures, and how to think about ISA-95 in the world of Unified Namespaces. Be sure to check out our eBook: Unified Namespaces: The Ultimate Guide. 在这篇文章中,我们将讨论ISA-95的“是什么”和“为什么”,以及它在现代控制系统中的适用和不适用之处。我们将概述在设计企业系统架构时实际需要了解的ISA-95知识,以及如何在统一命名空间的世界中思考ISA-95。请务必查看我们的电子书《统一命名空间:终极指南》。 # The 4 Ws of ISA-95 ## Who Created ISA-95, and When? ISA-95中的ISA代表国际自动化协会。他们是一个非营利性的标准化组织,专注于仪器仪表、系统和自动化领域。ISA制定并维护着制造业界各种主题的标准。 https://www.isa.org/standards-and-publications/isa-standards ISA-95始于1995年,并不断修订和更新,以应对现代技术的进步,包括来自“工业4.0”兴起的变化。 The ISA in ISA-95 stands for the International Society of Automation. They are a non-profits standards body for the fields of instrumentation, systems, and automation. ISA develops and maintains standards for all manner of topics in the manufacturing world. ISA-95 began life in 1995 and has been continually revised and updated to account for modern technological advancements—including changes from the rise of "Industry 4.0". ## What Is ISA-95? ISA-95的正式名称是“企业-控制系统集成”。它描述了制造企业的总体层次结构,包括: 第四级 - 商业计划和物流 第三级 - 制造业务和控制 第二级 - 自动化 第一级 - 现场设备和功能 ISA-95 is officially titled "Enterprise-Control System Integration". It describes the overall hierarchy of manufacturing businesses including: Level 4 - Business Planning and Logistics Level 3 - Manufacturing Operations and Control Level 2 - Automation Level 1 - Field devices and functions This hierarchy concept is also referred to as the “Automation Pyramid.”  The Automation Pyramid - Process Equipment up to Business Systems 这种层次结构概念也被称为“自动化金字塔”。 自动化金字塔 - 从工艺设备到商业系统 除了自动化金字塔概念之外,ISA-95还详细说明了如何以“生产模型”的形式描述制造过程,以及如何定义和实现制造业务与企业本身之间的集成。标准的较新部分讨论了如何管理制造业务中各个系统之间的信息流和消息传递。 Beyond the automation pyramid concept, ISA-95 also details how to describe manufacturing processes in the form of a "production model", how to define and implement integrations between manufacturing operations and the business itself. The more recent parts of the standard discuss how to manage the flow of information and messaging between the various systems in a manufacturing operation. ## Why Does ISA-95 Exist? 随着制造技术的复杂化,计算能力与工厂生产线以及网络连接一同整合。在没有像ISA-95这样的框架来管理一切的情况下,理解和管理这些日益复杂的交互变得困难。 坦率地说,ISA-95的存在还因为非营利并不等于开源。这也意味着ISA能够将ISA-95标准以可观的价格出售给许多公司。 As manufacturing technology became more complex, computing power was integrated with the plant floor along with network connectivity. Without a framework like ISA-95 to manage everything, it became difficult to understand and manage these increasingly complex interactions. To be blunt, ISA-95 also exists because non-profit does not mean open source. This also means that ISA is able to sell the ISA-95 standard to many companies for a decent sum. # ISA-95 In Detail 在撰写本文时,ISA-95标准共有八个部分,以及一个补充数据模板。您可以在主要的ISA标准页面上阅读每个部分的标题和简要描述。总体而言,ISA-95包含了大量信息,并可以与技术平台结合使用,构建出一个优秀的系统。但是,在线搜索时,您会发现您可以访问的关于ISA-95的大部分信息仅占第1部分的前20%! At the time of this writing, the ISA-95 has eight parts plus a supplemental data template. You can read the titles and a brief description of each on the main ISA Standards page. Combined, the ISA-95 is a huge amount of information and could be used in conjunction with technology platforms to build out a great system. But when searching online, you will find that most of the information about ISA-95 you can access is only the first 20% of Part 1!  ## ISA-95 Part 1: Models and Terminology 5 层次模型 5.1层次模型介绍 5.2功能层次 5.3基于角色的设备层次 5.4实物资产设备层次 6功能数据流模型 6.1功能数据流模型内容 6.2功能数据流模型的符号 6.3功能性模型 6.4功能 6.5信息流 7制造运行管理 7.1制造运行管理活动 7.2制造运行管理类别 7.3制造运行管理内的其他活动 7.4制造运行管理资源 8 信息模型 8.1 模型解释 8.2制造运行信息类别 ISA-95标准的第1部分概述了不同的模型和抽象级别,以全面理解和映射制造业务和企业系统集成。 该标准从领域级别的定义开始(控制系统和企业系统)。这包括每个领域的功能,ISA-95感兴趣的功能,以及信息如何通过这些功能流动、相关信息的类别以及信息如何定义。 ISA-95侧重于金字塔的第3和第4级之间的集成(制造业务和控制以及商业计划和物流)。它还将定义企业级别的操作,它们如何与制造业务水平的操作集成,以及我们如何需要构建每个业务级别的模型,以便在第3和第4级之间进行有效的通信。 除了自动化金字塔外,第1部分还描述了工厂的生产模型。 生产模型通常被称为“企业->场地->区域->生产线”模型。 Part 1 of the ISA-95 standard outlines the different models and levels of abstraction for fully understanding and mapping out manufacturing operations and business system integrations. The standard begins with domain level definitions (control systems and enterprise systems). This includes functions in each domain, functions of interest to ISA-95—along with how information flows through the functions, the relevant categories of information, and how the information is defined. Keep in mind that ISA-95 focuses on the integration between levels 3 and 4 of the pyramid (Manufacturing Operations and Control, and Business Planning and Logistics). It will also define operations at the enterprise level, how they integrate with operations at the manufacturing level, and how we need to structure the model of every business level to effectively communicate between Levels 3 and 4. Along with the automation pyramid, Part 1 also describes the plant’s production model. The production model is commonly referred to as the "Enterprise->Site->Area->Line" model. 大多数关于ISA-95的在线内容都集中在这个模型上,这是有充分理由的。 理解标准的这一部分至关重要,因为它将指导您如何构建整体系统架构。这也是跟踪OEE的最简单方法之一,OEE是MES集成中最常见的第一步之一。 在没有使用OEE这个术语的情况下,ISA-95第1部分描述了作为整体对象模型的一部分捕获计算OEE所需的所有数据。设备状态和计划生产时间(可用性)、生产能力(吞吐量)、生产规则(质量)是在生产模型之上叠加的概念。它们使您能够构建工厂的表示,并了解从OEE角度它是如何运作的。这些工具允许您构建一个过程能力模型——本质上,是在构建您的操作模型时免费计算OEE的能力。 不幸的是,这是大多数文章在解释ISA-95时停止的地方,主要是因为当您只关注OEE时,它提出了一个坚实的观点。 这是令人遗憾的,因为第1部分还包括了使用功能性企业-控制模型描述制造业务中最常见的业务功能的详细分析。 Most online content about ISA-95 focuses on this model—and for good reason. It’s vitally important to understand this part of the standard, because it will inform how you architect your overall system. This is also the simplest way to approach tracking OEE, one of the most common first steps into an MES integration. Without using the term OEE, ISA-95 Part 1 describes everything you need to capture the data for calculating OEE as part of an overall object model. Equipment Status and Scheduled Production time (Availability), Production Capacity (Throughput), Production Rules (Quality) are concepts layered on top of the production model. They give you the ability to build a representation of your plant, and understand how it is operating from an OEE perspective. These tools allow you to build a process capability model—essentially, the ability to calculate OEE for free while you are building out the model of your operation. Unfortunately, is where most articles stop when explaining ISA-95, mainly because it makes a solid point when you are looking only at OEE. This is sad because Part 1 also includes a detailed breakdown of the most common business functions in a manufacturing operation using the Functional Enterprise-Control Model.  The Functional Enterprise-Control Model 功能性企业-控制模型 描述了企业的运作方式。如果考虑到统一命名空间的概念,这包括您需要捕获的企业“事件”,以便在任何时刻完整地快照您的业务。 The Functional Enterprise-Control Model describes how a business operates. If you consider the concept of a Unified Namespace, this encompasses all of the "events" of the business you need to capture for a complete snapshot of your business at any given point in time. ==The Functional Enterprise-Control Model includes:== 订单处理 生产排程 生产控制 维护管理 质量保证和控制 运营规划 库存管理 发货和收货 研发 市场营销和销售 Order Processing Production Scheduling Production Control Maintenance Management Quality Assurance and Control Operations Planning Inventory Management Shipping and Receiving R&D Marketing and Sales 该模型描述了这些操作如何作为不同部门和制造商品各部分之间的粘合剂,以及如何管理各个领域之间的数据定义和流动。它甚至提供了许多如何运用ISA-95思维构建与供应商无关系统的示例(并附有达成标准的说明)。 ISA-95第1部分包含了大量有关如何设计系统的优秀信息,即使一些如何将数据从A点传输到B点的具体细节随着技术进步(如MQTT等)而有所改进。 The model describes how these operations act as the glue between different departments and parts of manufacturing goods, along with how to manage the data definitions and flow between each of the areas. It even has plenty of examples of how to use the ISA-95 mindset for building vendor-agnostic systems (with receipts for how they arrived at the standard). Seriously, if you haven't read ISA-95 Part 1, it is worth the time! It has a TON of great information for how to architect systems—even if some of the specifics of HOW to get data from point A to point B have been improved with technological advancements like MQTT. ## ISA-95 Part 2: Objects and attributes for enterprise-control system integration 如果我们把ISA-95第1部分看作是我们将在ISA-95 101中学到的一切的概要,那么接下来的部分将详细介绍特定主题。应用第2部分中的概念将为您提供一组标准化的定义和术语,以便在您业务的所有元素之间进行清晰的沟通——无论是自动化数据交换还是人际沟通。 4对象模型属性 4.1信息模型 4.2通用建模信息 4.3通过特性实现属性的可扩展性 4.4对象模型结构 4.5表的解释 4.6模型关系 4.7层次范围 4.8值的类型 5通用对象模型 5.1人员信息 5.2基于角色的设备信息 5.3实物资产信息 5.4物料信息 5.5过程段 5.6容器、工具和软件 6运行管理信息 6.1运行定义信息 6.2运行调度信息 6.3运行绩效信息 6.生运行能力信息 6.5过程段能力信息 7.对象模型的相互关系  8.对象列表 |对象|模型| |--|--| 人员类|人员模型 人员类特性|人员模型 人|人员模型 人的特性|人员模型 资质测试规范|人员模型 资质测试结果|人员模型 设备类|设备模型 设备类特性|设备模型 设备|设备模型 设备特性|设备模型 设备能力测试规范|设备模型 设备能力测试结果|设备模型 实物资产|实物资产模型 实物资产特性|实物资产模型 实物资产类|实物资产模型 实物资产类特性|实物资产模型 实物资产能力测试规范|实物资产模型 实物资产能力测试结果|实物资产模型 设备资产映射|实物资产模型 物料类|物料模型 物料类特性|物料模型 物料定义|物料模型 物料定义特性|物料模型 物料批次|物料模型 物料批次特性|物料模型 物料分批次|物料模型 物料测试规范|物料模型 物料测试结果|物料模型 物料集合|物料模型 物料定义集合|物料模型 物料类集合|物料模型 过程段|过程段模型 过程段参数|过程段模型 人员段规范|过程段模型 人员段规范特性|过程段模型 设备段规范|过程段模型 设备端规范特性|过程段模型 实物资产段规范|过程段模型 事物资产段规范特性|过程段模型 物料段规范|过程段模型 物料段规范特性|过程段模型 物料段规范集合|过程段模型 过程段从属性|过程段模型 运行定义|运行定义模型 运行物料清单|运行定义模型 运行物料清单项目|运行定义模型 运行段|运行定义模型 参数规范|运行定义模型 人员规范|运行定义模型 人员规范特性|运行定义模型 设备规范|运行定义模型 设备规范特性|运行定义模型 实物资产规范|运行定义模型 实物资产规范特性|运行定义模型 物料规范|运行定义模型 物料规范特性|运行定义模型 物料规范集合|运行定义模型 运行段从属性|运行定义模型 运行调度|运行调度模型 运行请求|运行调度模型 请求段响应|运行调度模型 段要求|运行调度模型 段参数|运行调度模型 人员要求|运行调度模型 人员要求特性|运行调度模型 设备要求|运行调度模型 设备要求特性|运行调度模型 实物资产要求|运行调度模型 实物资产要求特性|运行调度模型 物料要求|运行调度模型 物料要求特性|运行调度模型 物料要求集合|运行调度模型 运行绩效|运行绩效模型 运行响应|运行绩效模型 段响应|运行绩效模型 段数据|运行绩效模型 人员实际|运行绩效模型 人员实际特性|运行绩效模型 设备实际|运行绩效模型 设备实际特性|运行绩效模型 实物资产实际|运行绩效模型 实物资产实际特性|运行绩效模型 物料实际|运行绩效模型 物料实际特性|运行绩效模型 物料实际集合|运行绩效模型 运行能力|运行能力模型 人员能力|运行能力模型 人员能力特性|运行能力模型 设备能力|运行能力模型 设备能力特性|运行能力模型 实物资产能力|运行能力模型 实物资产能力特性|运行能力模型 物料能力|运行能力模型 物料能力特性|运行能力模型 物料能力集合|运行能力模型 过程段能力模型|过程段能力模型 产品定义|产品定义模型 产品段|产品定义模型 制造清单|产品定义模型 制造清单集合|产品定义模型 生产调度|生产调度模型 生产请求|生产调度模型 生产参数|生产调度模型 生产绩效|生产绩效模型 生产响应|生产绩效模型 生产数据|生产绩效模型 生产能力|生产绩效模型 ISA-95第2部分侧重于ISA-95中我们拥有的制造业务==层次结构3和4之间的界面==,包括: 生产能力(对OEE有用) 过程段(对产品实际生产/物料流动有用) 人员和设备模型 材料 生产排程和性能 生产路由和物料依赖性 If we think of ISA-95 Part 1 as an outline of everything we will learn in ISA-95 101, the following parts will detail specific topics. Applying the concepts in Part 2 will give you a standardized set of definitions and terminology for clear communication across all elements of your business—for automated data exchanges, as well as person to person communication. ISA-95 Part 2 focuses on the the interface between manufacturing business hierarchy levels 3 and 4 for the models we have in ISA-95, including: Production capability (useful for OEE) Process segments (useful for how products are actually produced/flow of materials) Personnel and equipment models Materials Production scheduling and performance Production routing and material dependencies 这些模型再次被描述(与第1部分类似),但这次第2部分描述了每个模型可能具有的许多潜在属性,您可能希望在构建自己的模型时使用这些属性。这些属性在表格中进行描述,包括描述、依赖关系、值,以及典型场景的示例,以及如何将模型链接在一起,从数据角度全面了解您的操作。 公正地说,说人们不谈论第2至第8部分和附加模板有些不太诚实。通常,不必详细讨论它们也可以理解主要概念。 第2部分及之后描述了在项目中为构建符合ISA-95标准的解决方案所需的大部分工作。 These models are described again (similarly as in Part 1), but this time Part 2 describes each model’s many potential attributes you may want to use when architecting your own models. These attributes are represented on tables including descriptions, dependencies, values, with examples of typical scenarios, and how to link models together for gaining a full understanding of your operation from a data perspective. To be fair, it is slightly disingenuous to say people DON'T talk about parts 2-8 and the supplemental template. Often, it’s not necessary to talk about them in detail to understand the major concepts. Part 2 and beyond describe the bulk of the work for architecting an ISA-95 compliant solution on a project. ## ISA-95 Part 3: Activity Models of Manufacturing Operations Management 第2部分侧重于如何==对您的设备、过程段和材料进行建模==, 而第3部分则帮助您==定义和标准化业务流程==。 这些流程包括: 生产 质量控制 维护 库存管理 报告和数据收集 排程和性能分析 维护 现在,您可以构建一套标准的运营活动,以与您的对象模型集成,描述您的操作是如何结构化的,以及在您业务的层次结构内工作是如何进行的。这使得第4级物流和规划功能与第2级手动和自动化过程控制功能之间实现了集成。 这些概念鼓励公司在整个公司范围内采用最佳实践,并帮助您将制造业务与其他企业系统集成起来。 第3部分的好处包括系统之间的增强集成、公司内更好的沟通,以及对制造业务的改进理解。最终,这将导致提高运营效率、降低成本,并提高制造业的竞争力。 Where Part 2 focuses on how to model your equipment, process segments, and materials, Part 3 helps you define and standardize your business processes. These processes include: Production Quality control Maintenance Inventory management Reporting and data collection Scheduling and performance analysis Maintenance Now, you can build a standard set of operations activities to integrate with your object model for describing how your operation is structured, and how work is done within the hierarchy of your business. This enables integration between level 4 logistics and planning functions and level 2 manual and automated process control functions. These concepts encourage adopting best practices across the company, and help you integrate your manufacturing operations with other enterprise systems. The benefits to Part 3 are enhanced integration between systems, better communication across your company, and improved understanding of manufacturing operations. Ultimately, this will result in increased operational efficiency, reduced costs, and improved competitiveness in the manufacturing industry. ## ISA-95 Part 4: Objects and Attributes for Manufacturing Operations Management Integration 第4部分在第3部分的基础上进行了拓展,定义和规范了对象和活动模型==如何与其他系统集成和使用==。 它展示了如何通过清晰地说明如何将数据从一个系统传递到另一个系统来改进组织内部的沟通,以及人们如何利用这些数据更有效地完成工作。 ISA-95第4部分详细阐述的概念产生了诸如减少达到最佳生产水平所需的时间和成本之类的好处。 这是通过以下方式实现的: 使供应商能够提供与您现有系统集成的适当工具和技术 帮助您的用户和利益相关者确定他们对新工具的需求 减少集成和自动化制造过程的总体成本 优化您的供应链和产品在设施内的流动 减少整体工程生命周期成本的集成工作 Part 4 builds on Part 3 to define and standardize how object and activity models can be used and integrated with other systems. It shows how to omprove communication across the organization by clearly spelling out how to get data from one system to another—and how people can use that data to do their jobs more efficiently. The concepts detailed in ISA-95 Part 4 produce benefits such as reducing the time and cost to reach optimal production levels. This is accomplished by: Enabling vendors to supply the appropriate tools and technology to integrate with your existing systems Helping your users and stakeholders determine their needs for new tools Reducing the overall cost of integrating and automating manufacturing processes Optimizing your supply chain and movement of goods through your facility Reducing overall engineering lifecycle costs for integration work ## ISA-95 Part 5: Business-to-Manufacturing Transactions 第5部分借鉴了第3部分和第4部分的概念,并定义了实际整合不同系统的“动词”。这类似于思考Web服务器如何使用PUT、GET和POST请求将数据从A点传递到B点。 与第3部分和第4部分类似,ISA-95第5部分侧重于对象和活动的相同模型,并利用第2部分的数据模型来定义在系统集成时将发送哪些数据以及何时发送。 总体而言,第5部分概述了==与工作绩效和质量相关的信息的结构、内容和格式,这些信息需要在制造业运营管理系统与其他企业系统之间进行交换==。 ==第5部分提供了一个在系统之间传递数据的标准化模型==。 现在,您可以通过定义要集成的数据以及将如何在系统之间集成来轻松规划集成。 第5部分所描述的方法的好处在于解耦了特定供应商的实现,因此您可以使用标准协议和数据集成方法。它还简化了您对整个制造运营系统涉及的任何人的集成需求描述方式。 应用application 物理和虚拟过程的有序集合,由管理完成定义对象的事务集合的一组资源执行;一个事务中涉及执 行该行为的信息提供者和信息使用者。 消息message 一个发送应用与一个或多个接受应用间的被单向传送的结构化信息单元。 事务transaction 执行于第3层和第4层行为的应用之间交换的有关消息序列。 名词noun 信息内容的两个部分之一,据IEC 622,64,1和IEC 62264一2中定义,代表一个或多个对象。 动词verb 信息内容的两个部分之一,定义了执行的行为或对请求的响应。 事务由一系列的消息组成,其中每条消息都具有一个结构,并已定义在4.2中。 消息同时包含一个动词区域和一个名词区域。消息的名词区域包含消息中信息的传递;消息的动 词区域包含与信息相关的行为。 触发事务应用的作用决定了用于事务管理的一系列动词。这些事务模型在4.2中进行了详细叙述 定义了三类不同的事务模型: l)拉事务模型 2)推事务模型 即数据使用者向数据提供者请求数据。 即数据提供者请求得到其他使用者的一个数据处理行为(处理、更改、取消)。 3)发布事务模型,即数据所有者向使用者(用户)发布数据。 注1:“数据所有者”一词用于描述负责加强数据一致性的应用程序。 注2:本部分没有解决多重系统都可能作为数据所有者的问题。在此种情况下,应当建立一种结构,指定一个主要 的数据所有者,同时其他系统充当数据使用者的角色。              Part 5 takes the concepts from Parts 3 and 4 and defines the "verbs" which actually integrate different systems. This is similar to thinking about how a web server uses PUT, GET, and POST requests to get data from point A to point B. Similar to Parts 3 and 4, ISA-95 Part 5 focuses on the same models for objects and activities, and utilizes the data models from Part 2 to define which data will be sent where, when integrating systems. Overall, Part 5 outlines the structure, content, and format of the information related to work performance and quality that needs to be exchanged between manufacturing operations management systems and other enterprise systems. Part 5 provides a standardized model for passing data between systems. Now, you can easily spec out integrations by defining which data will be integrated and how it will be integrated between systems. The benefit to the approach described in part 5 is a decoupling of vendor specific implementations so you can use standard protocols and approaches to data integrations instead. It also streamlines how you will describe integration requirements for anyone involved with your manufacturing operations systems as a whole. ## ISA-95 Part 6: Messaging Service Model 如果您从统一命名空间的角度来看ISA-95,那么第6部分就是适合您的! 可以说,在2023年之后,诸如MQTT和Sparkplug B等技术被广泛采用后,第6部分变得不那么相关了。 尽管如此,ISA-95第6部分仍然具有一些出色的概念和最佳实践。 第6部分定义了消息服务模型(MSM)的概念,作为一种规定在不同系统之间通信时数据如何转换的方式。 总体而言,第6部分是在考虑具有不同数据结构的不同应用程序时,位于第2、4和5部分之上的一层。 基本上,每个应用程序收集“本地”数据,将其转换为“全局”格式,将“本地”名称转换为适用的“全局”名称,然后将数据发送到交换服务。然后,另一个系统摄取数据,使用它,然后发送任何必要的响应。 ISA-95第6部分的要点是,您必须定义您的对象和活动模型,并定义您的数据将如何被转换为将使用它的各种系统。第6部分中定义的工作不能通过在每个定义中使用Sparkplug B来替代。相反,Sparkplug B可以处理将数据发送到系统的“信息交换服务”部分的任务。使用第6部分来帮助定义如何在本地和全局范围之间进行转换。 稍微开个玩笑,第6部分是在2014年发布的,那时比2023年更加相关。在今天的世界中,我们可以简单地用以下内容替换第6部分的所有内容:“在集成任何内容之前,请使用统一命名空间和MQTT,并就命名约定达成一致。” If you are looking at ISA-95 through the lens of a Unified Namespace Part 6 is for you! It could be argued that Part 6 is less relevant in 2023 after the wide adoption of technologies like MQTT and Sparkplug B. Although, ISA-95 Part 6 still has some great concepts and best practices. Part 6 defines the concept of a Messaging Service Model (MSM) as a way to specify how data is transformed when communicating between disparate systems. Overall, Part 6 is a layer on top of Parts 2, 4, and 5 when considering different applications with different data structures. Essentially, each application collects "local" data, converts it into the "global" format, converts "local" names to "global" names where applicable, and sends data to the exchange service. Then, the other system ingests the data, uses it, and then sends any required responses. The key takeaway of ISA-95 Part 6 is that you must define your object and activity models as well as define how your data will be translated to the various systems which will be using it. The work defined in Part 6 cannot be replaced by using Sparkplug B for every definition. Instead, Sparkplug B can handle the task of sending data to the “Information Exchange Service” portion of the system. Use Part 6 to help define how to translate between local and global scopes. To poke a little fun, Part 6 was released in 2014, and was much more relevant back then than it is in 2023. In today's world, we can simply replace all of Part 6 with: "Use a Unified Namespace and MQTT, and agree on your naming convention before you integrate anything." ## ISA-95 Part 7: Alias Service Model 在不直接明说的情况下,使用统一命名空间的建议是: ISA-95的第7部分基本上就是第6部分,只不过它更详细地增加了在系统之间交换数据时“将本地名称转换为全局名称”的任务。考虑到自ISA-95最初实施以来技术的发展,这意味着现在需要更多地考虑第7部分。 虽然MQTT和Sparkplug B可以轻松处理向信息交换服务发送数据,但考虑到制造组织中潜在的集成数量,您将需要花费比以往任何时候更多的时间和精力来处理命名约定方面的事务。您将需要为系统的每次集成将数据从全局命名空间转换为本地命名空间,并且您可以使用ISA-95中概述的概念来帮助您进行转换。 Tell me to use a Unified Namespace without telling me... ISA-95 Part 7 is basically Part 6, except it adds more detail to the "convert local names to global names" task of exchanging data between systems. Given the advent of technology since ISA-95 was originally implemented, this means that Part 7 is now much more important to consider. While MQTT and Sparkplug B can easily handle sending data to the Information Exchange Service, with the number of potential integrations across a manufacturing organization you will need to spend more time and energy than ever on the naming convention side. You will need to convert data from a global namespace to a local namespace for every integration with your system and you can use the concepts outlined in ISA-95 to help. ## ISA-95 Part 8: Information Exchange Profiles ISA-95的第8部分定义了一种框架,用于标准化信息配置文件,您可以使用这些配置文件将不同的技术以“ISA-95方式”整合在一起。 它更偏向于构建具有ISA-95集成功能的软件的软件供应商。例如:我的软件包,使用第8部分的信息交换配置文件构建,可以通过第6/7步骤将数据以“ISA-95方式”发送到任何需要的其他软件包,然后它可以摄取我的数据并对其进行处理。每个人都以不同的方式(如果在今天的世界中还有的话)实施他们的ISA-95,这使得第8部分感觉像是“来得太迟了”。 即使不同的软件公司实施了信息交换配置文件,您仍然需要努力确保您的命名约定与所有其他人一致——就像第6和第7部分一样。值得庆幸的是,您可以在统一命名空间中轻松实现所有这些,而不必担心实施信息交换配置文件。 I'm a people person, I have people skills Meme from Office Space Let's be honest. Part 8 seems like the guy in Office Space who deals with the engineers so the people don't have to! ISA-95 Part 8 defines the framework for standardized information profiles you can use to integrate different technology together in an "ISA-95 way". It is more geared towards software vendors which build software with ISA-95 integrations out of the box. For example: My software package, built with a Part 8 Information Exchange Profile, can send data in an "ISA-95 way" to any other software package that requires it—through a Part 6/7 process—and then it can ingest my data and do something with it. The fact that everyone does their ISA-95 implementations differently (if at all in today's world) makes Part 8 feel like “too little too late”. Even if different software companies implement Information Exchange Profiles, you will still need to make the effort to ensure that your naming conventions match across the board—as in Parts 6 and 7. Thankfully, you can easily accomplish all of this in a Unified Namespace without worrying about implementing Information Exchange Profiles. Maybe it is good to still have Part 8? It is not very applicable in 2023, other than ISA needs to put it out there as an attempt to stay relevant despite technological advancements making parts of ISA-95 obsolete. 或许保留第8部分仍然是有益的?在2023年,除了ISA需要发布它作为一种努力保持相关性的尝试,尽管技术进步使得ISA-95的某些部分变得过时之外,它并不是非常适用。 ## ISA-95 TR01: Master Data Profile Template This is geared towards people who want to develop ISA-95 compliant software. Our assessment of Part 8 also applies here. 这是为那些希望开发符合ISA-95标准软件的人而设计的。我们对第8部分的评估在这里同样适用。 # Where Does ISA-95 Fall Short? ISA-95在哪些方面存在不足? ISA-95的1-5部分在发布时非常强大。建模制造组织、定义数据结构、定义各种工具和系统如何集成,并利用公司内有价值的数据和信息的整体概念,至今仍然具有强大的概念。 然而,在当今统一命名空间、MQTT、Sparkplug B、基于云的分析软件包和更加标准化的平台的世界中,ISA-95似乎已经错过了时机。 可以说,第6-8部分的概念在今天仍然非常相关,但是它们假设在不同公司和业务单元之间将进行太多的标准化,以至于单独使用时价值不高。现在,我们有了出色的替代方案,可以建立标准化的命名约定并将数据发送到集中的信息交换中心。当使用MQTT和Sparkplug B时,几乎可以免费获得这些功能。 ISA-95遇到困难的另一个领域——无论是现代通信协议还是其他协议——是在处理复杂流程时。ISA-95基本上采用了树型模型的方法。对于企业->站点->区域->生产线类型的制造流程,它的表现非常出色。对于这种方法,“将原材料投入线性生产线,然后从另一端输出成品”非常适用。 当制造流程出现分支生产线、并行流程甚至具有复杂操作要求的机器时,ISA-95就会出现问题。这些情况在标准设备层次结构中建模可能会很困难,并且在需要计算OEE时可能需要一些有趣的变通方法。 ISA-95 Parts 1-5 were pretty powerful when they came out. The overall concept of modeling a manufacturing organization, defining the data structures, defining how various tools and systems would be integrated, and utilizing valuable data and information across the company are still powerful concepts today. But, ISA-95 feels like it has missed the ball in today's world of Unified Namespaces, MQTT, Sparkplug B, cloud-based analytics packages, and more standardized platforms in general. You could argue that the concepts in parts 6-8 are still highly relevant today, however they assume too much standardization will be done across different companies and business units to be valuable on their own. Now, we have great alternatives for building out standardized naming conventions and sending data to a centralized Information Exchange. You get it almost for free when using MQTT and Sparkplug B. Another place where ISA-95 runs into roadblocks—modern communication protocols or not—is with complex processes. ISA-95 essentially follows a tree model approach. It does really well with the Enterprise->Site->Area->Line types of manufacturing processes. "Take raw materials, feed them into a linear production line, and stuff comes out the other end" works really well for this approach. ISA-95 breaks down when there are branching production lines, parallel processes, or even machines with complex operational requirements. These can be difficult to model in the standard equipment hierarchy and lead to some interesting workarounds when you need to calculate OEE. Since ISA-95 is a layer of abstraction, and isn't necessarily focused on the most granular details at the production line level, some hand-waving arguments and simplifying a complex machine into a work cell isn't the end of the world. After all, ISA-95 is an abstraction for easier communication within an organization to understand how a process is operating at any given point in time. If you can get an idea of a complex process’s health even if it isn't 100% accurate in full HD quality, you will still get about 95% of the value without having to do the last 95% of the work for that last 5% level of detail. 由于ISA-95是一种抽象层,并不一定专注于生产线级别的最细节,因此一些模糊的论点和将复杂机器简化为工作单元并不是世界末日。 毕竟,ISA-95是一种抽象,用于在组织内更容易地进行沟通,了解过程在任何给定时间点的运行情况。 即使在完全高清质量上不是100%准确,如果您能对复杂流程的运行状况有一个大致的了解,您仍然可以获得大约95%的价值,而无需为最后5%的细节工作做最后的95%。 # Wrapping Up 总结一下 总的来说,ISA-95是一个坚实的框架,在2023年仍然具有很多适用性,即使对于复杂的制造流程也是如此。 尽管当今的许多可用技术为我们提供了许多ISA-95的好处(命名结构和部分6-7将数据发送到其他系统),但现代工具如MQTT、Sparkplug B和统一命名空间基本上是免费的,但我们也生活在一个受ISA-95启发的世界。这些较新的技术都不是在一个封闭的环境中开发出来的。 Overall, ISA-95 is a solid framework and still has a lot of applicability in 2023—even for complex manufacturing processes. Though much of today’s available technology gives us many of the benefits of ISA-95 (structure in naming, and parts 6-7 to send data to other systems) essentially for free with modern tools like MQTT, Sparkplug B, and Unified Namespaces, we also live in a world informed by ISA-95. None of these newer technologies were built in a bubble. 在某种程度上,这有点像向Z世代介绍披头士乐队。他们可能不会对披头士乐队感到惊讶,因为披头士乐队之后的所有音乐都存在于披头士乐队之前的世界中。如果你在披头士乐队出现时就在场(或者你看看他们对之后所有音乐的遗产和影响),你就能看到他们的强大,今天仍然欣赏他们的伟大之处。 In a way, it sort of feels like introducing Gen Z to The Beatles. They might not be amazed by The Beatles because all the music post-Beatles existed in a world where The Beatles came first. If you were around when The Beatles came about (or you look at their legacy and influence on all of music that came after), you can see how powerful they are, and still appreciate their greatness today. 我们希望您喜欢我们的博客,如果您希望在Corso Systems网站上看到其他主题,有任何问题,请与我们联系!或者如果您想与我们讨论在您的公司实施ISA-95、统一命名空间或任何其他令人兴奋的技术,请告诉我们! We hope you’re enjoying our blog, if there are other topics you'd like to see on the Corso Systems website, have any questions please reach out and let us know! or want to talk to us about implement ISA-95, Unified Namespaces, or any other exciting technology at your company, https://corsosystems.com/posts/isa-95-101

智能制造CEO

2024年3月23日 15:03

分享文档

收藏文档

上一篇

下一篇

微信扫一扫

复制链接

手机扫一扫进行分享

复制链接

关于 MrDoc

觅思文档MrDoc

是

州的先生

开发并开源的在线文档系统,其适合作为个人和小型团队的云笔记、文档和知识库管理工具。

如果觅思文档给你或你的团队带来了帮助,欢迎对作者进行一些打赏捐助,这将有力支持作者持续投入精力更新和维护觅思文档,感谢你的捐助!

>>>捐助鸣谢列表

微信

支付宝

QQ

PayPal

Markdown文件

分享

链接

类型

密码

更新密码